Why Are Laser Machines Particularly Suitable for Manufacturing Medical Components?

A case study on laser processing systems in the field of medical technology. Basic information for selecting laser manufacturing technologies and advantages that laser machines offer in the manufacture of medical components.

The use of advanced laser manufacturing technologies offers immense production potential for medical device components. Today, despite the broad availability of information, deep expertise is essential to properly evaluate the appropriate processing technology. At Pulsar, we have spent more than ten years focusing intensively on productive applications in laser micro‑machining—especially in areas such as material suitability, scalability through automation, software solutions, and quality assurance. We believe these are the most relevant topics for medical technology.

This article provides foundational insights for selecting laser manufacturing technologies for medical‑grade applications. We highlight a number of key advantages that laser machines offer in the production of medical components.

State of Manufacturing Technology for Medical Components in 2025

Miniaturization and electrification continue to drive medical device development. In particular, the proliferation, acceptance, and usability of smartphones have accelerated the integration of sensors and electronics in medical technology. Smart medical devices with app integration are already on the market. These advances, combined with the high demands in medical manufacturing for cleanliness and functionality, have led to complex process workflows. While medical industry development cycles differ from the electronics sector, they too are under pressure to reduce time‑to‑market and enable new applications. For these high‑performance production systems to be economically viable, machines must support platform or variant manufacturing.

Advantages of Laser Machines in Medical Component Production

Even beyond electronic applications, the benefits of laser machines have been known for years: their high precision and resolution (laser diameters typically around 15 µm), flexibility via digital parameterization, and non-contact, wear-free processing are compelling. These strengths explain the continued proliferation of laser processes across virtually all material groups used in medical manufacturing. The industrial maturity of ultrashort‑pulse (USP) laser technology over the past decade has truly revolutionized the processing of critical materials and composites used in medical devices.

Precision Processing of Medical Materials with USP Lasers

Titanium alloys have been used for decades in medical products due to their excellent material-specific and physiological properties. Ceramic materials—with their biocompatibility and sterilizability—are also widely used (for instance, in implants). Their insulating properties are essential for use in electronic sensor systems. Stainless steels and various glass materials remain common in medical component manufacturing.

Today's electronic sensor systems are often built as multilayer structures of alternating insulating and conductive films, typically just 20–200 µm thick. These materials are difficult to machine conventionally and sensitive to tool contact—making them ideal candidates for precise processing using USP laser technologies.

No Carbonization During USP Laser Cutting of Medical Parts

Medical components such as films, catheters, tubing, implants, and three‑dimensional parts are often made from polymers—like polyethylene (PE), polyimide (PI), polystyrene (PS), or polypropylene (PP). While PVC can be laser processed, its thermal behavior and phthalate-containing plasticizers make it less desirable for medical use.

With conventional CO₂ lasers, the material in the cut zone sublimates—heating and burning off, resulting in thermal damage and visible brown or black edges. This pyrolysis, known as carbonization, generates harmful decomposition products—unacceptable for nearly all medical applications.

Only ultrashort‑pulse laser sources (USP) enable high-quality cutting of polymers. With pulse durations often in the femtosecond range and intensities exceeding 10¹³ W/cm², the illuminated material layer vaporizes faster than its heat can diffuse to neighboring areas. Simply put: the material disappears before it can heat surrounding regions. This process is often referred to as “cold ablation.”

Combining Multiple Laser Processes in a Single Machine for Medical Use

The high intensity of USP lasers makes them ideal for brittle, hard, or temperature-resistant materials. A laser machine typically includes: laser source, beam routing, focusing optics, and motion systems. The choice of the right USP source affects productivity, material suitability, and process quality. Optics determine spot size and depth of focus. Motion systems—such as machine axes, scan heads, and handling systems—enable various process options.

With the right combination of focusing and motion setup, a single laser machine can handle:

- Micro-drilling precise holes, vias, nozzles, and perforations,

- Cutting / separation using multi‑pass cutting at feed rates up to 1,000 mm/s,

- Ablation / cleaning (e.g. exposing layers, polishing),

-

Modification of material properties (optical, mechanical, chemical, tribological),

-

Marking / coding tasks like micro‑QR codes or serial numbers in almost any material.

Professional laser application centers can help assess feasibility, process capability, cycle time, scalability, and automation—especially for ramp‑up scenarios.

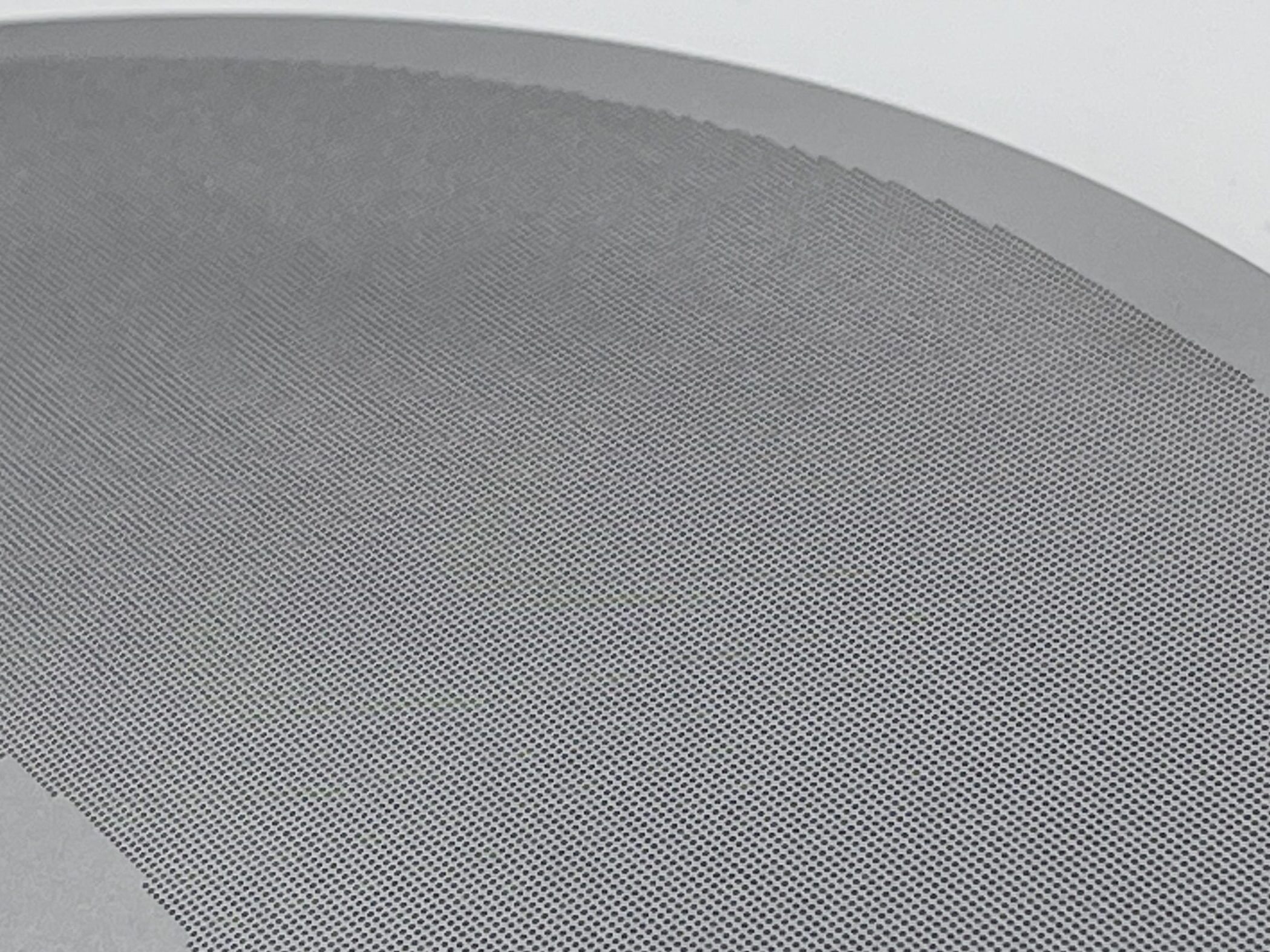

Laser machining of glass vials for the calibration of measuring instruments for the purpose of leakage testing. Targeted creation of holes in the micrometer range.

Automating Laser Machines for Medical Manufacturing

Reliable, high-volume production demands automation that ensures consistent part quality, machine availability, and cost control. Key automation aspects include:

-

CAD/CAM data integration,

-

Automated process control and tool change,

-

Handling systems for loading/unloading,

-

Integrated testing and measurement,

-

Interfaces to higher‑level systems (e.g. audit‑trail, ERP integration).

Which Handling Systems Work Best for Medical Parts?

Handling systems automate loading/unloading without manual intervention and manage material flow. Medical parts require:

-

Avoiding damage or contamination,

-

Maintaining cleanliness (no particulates),

-

Preventing contact with metallic components or lubricants,

-

Very precise micro-positioning for laser micro-machining.

Foil-based feeder systems (e.g. roll‑to‑roll or roll‑to‑sheet) are particularly suited for layered, polymer, conductive, or ceramic foils, typically 20–500 µm thick and up to ~300–500 mm width. High-end applications may combine robotic manipulators and vision systems: multi-axis robots with positioning accuracy well below 1 mm, vision systems offering ±20 µm tolerance, or even micro‑automation solutions for sub‑10 µm accuracy.

Laser processes are protected against manipulation

If, as described above, different processes can be implemented solely through digital parameterization, it is obvious that their correct and approved execution in the laser machine must be ensured. With the use of digital systems, the control software of the laser machines therefore takes on central importance.

Continuous compliance and verification of this compliance, both in the recipe and in the setting parameters used in the manufacturing processes, places special demands on the data integrity of the software systems used. Data integrity is understood here to mean the reliability and trustworthiness of the recorded measurement data and changes. From this, generally applicable procedural principles for software-supported data systems can be derived.

In this context, the regulations of the US FDA (see 21 CFR Part 11 Audit Trail Requirements) and the equivalent regulations of the British MHRA apply internationally to manufacturing processes in medical technology.

In the best case scenario, suitable machine software solutions for laser machines already meet data integrity requirements and include so-called audit trail solutions. These can then provide raw data and metadata to higher-level production control systems or ERP solutions. In a sense, the laser machine generates a “digital fingerprint” during the processing of a component, which is composed of the raw and metadata from the laser machine. Technologically, millisecond resolution and assignment to individual components, batches, and much more is possible here.

The functional scope of the database and audit trail solutions includes (excerpt):

- Operator identification systems and user level management

- Protected authentication systems

- Secure context-based menu navigation

- Protected recipe management

- Secure databases, including backup management

- Time-stamped data recording

- Raw data storage

- Machine condition monitoring (CMS)

- Developed interfaces to PLS and ERP systems, e.g. via OPC-UA

- Non-deactivable entry and change log (change log)

Our Conclusion from Experience…

USP laser machines are already successfully used for micro‑machining medical components across all material categories. They deliver significant production benefits when handling brittle, flexible, and sensor-equipped parts at micrometer precision. Standardized handling and vision systems (±20 µm accuracy, parts‑per‑minute throughput) and audit‑trail‑enabled software meet regulatory requirements. For further information on ramp‑up, micro‑automation, or machine options, visit our blog.