Aluminum adhesion with plasma & laser

Strong bonds, innovative solutions! Aluminum is lightweight but difficult to bond— until now. With our unique combination of plasma and laser treatment, we increase the adhesion of aluminum by up to 60%.

Mechanisms of adhesion improvement

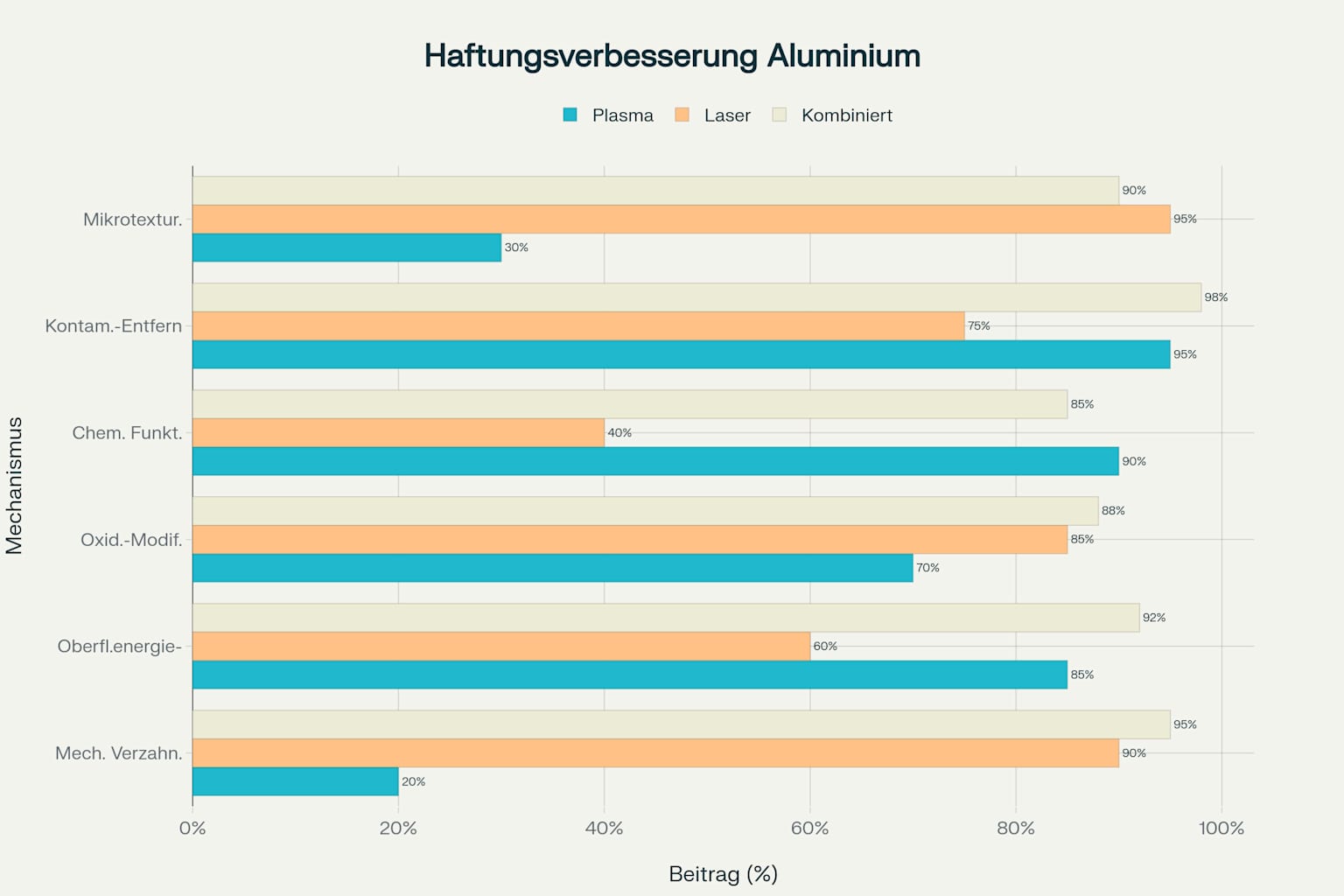

The combined treatment works via six basic mechanisms, each of which is influenced differently by plasma and laser:

Mechanisms for improving adhesion: contribution of plasma, lasers, and combinations thereof

Mechanical interlocking

The laser creates micro- and nanostructures with roughness values of 0.5–1.0 μm, which increase the effective surface area by 300%. Adhesives can penetrate these structures and form a form-fitting bond after curing.

Surface energy increase

Plasma activation increases the surface energy from 28 to 58 mJ/m² by generating polar functional groups. This significantly improves the wetting of adhesives— the contact angle with water decreases from 85° to 35°.

Oxide layer modification

Laser treatment modifies the natural aluminum oxide layer and creates a more active, adhesion-friendly surface chemistry. At the same time, the plasma removes loose oxide particles and organic contaminants.

Chemical functionalization

Atmospheric plasma generates up to 12 functional OH groups per nm² – a 500% increase compared to untreated surfaces. These groups form hydrogen bonds and covalent bonds with epoxy-based adhesives.

Contaminant removal

The combination achieves almost complete removal of lubricants, oxide residues, and organic contaminants. Plasma breaks down organic molecules, while the laser performs thermal ablative cleaning.

Microtexturing

Laser ablation creates precisely controlled surface structures in the micrometer range that are optimally matched to the viscosity and rheology of modern structural adhesives.

Practical application and process sequence

Six-step treatment process

Step 1: Pre-cleaning removes coarse contaminants and production residues by degreasing and dust removal. Residues from lubricants used in sheet metal processing are critical here.

Step 2: Laser surface modification uses Nd:YAG lasers with a wavelength of 1064 nm and pulse energies of 0.1-2 J/cm². The energy density and pulse overlap must be precisely controlled to produce optimal microtextures without thermal damage.

Step 3: Plasma activation takes place at atmospheric pressure with argon/oxygen mixtures for 30-60 seconds or, depending on the application, using clean compressed air. Treatment time and gas purity are critical parameters for reproducibility.

Step 4: Surface characterization checks the surface energy (>50 mJ/m²) and roughness (0.5-1.0 μm) achieved using contact angle measurements and profilometry.

Step 5: Adhesive application uses epoxy-based structural adhesives whose viscosity and curing behavior are adapted to the treated surface.

Step 6: Quality testing validates the achieved adhesion improvement of 50-70% through tensile shear strength tests and long-term aging.