From Concept to Series Production: R&D and Contract Manufacturing

From concept development to series production, Fischer Söhne AG is your reliable partner for customized plastics solutions – all from a single source. Our strength lies in combining engineering expertise with state-of-the-art manufacturing technologies to deliver tailored solutions for Life Science.

Development: Smart Solutions Start with Smart Engineering

Innovation starts in our Development department, where we create customer-specific solutions in close cooperation with our clients. From the initial concept to series production, our engineers apply their extensive expertise in:

- Product development and design

- Prototyping and validation

- In-house mould construction and toolmaking

Custom toolmaking for optimized mould performance

Custom toolmaking for optimized mould performance

This integrated approach ensures rapid implementation, flexible adaptation, and efficient production processes. Our focus: functional design, reliable manufacturability, and compliance with all industry standards.

Our in-house toolmaking enables maximum flexibility and ensures that your product reaches the market quickly and efficiently.

Production Excellence: Certified Quality in Cleanroom Conditions

Certified cleanroom production for high-precision plastic components

Certified cleanroom production for high-precision plastic components

At Fischer Söhne AG, quality begins in production. Using state-of-the-art injection moulding technologies, we manufacture high-precision plastic components in both standard and cleanroom environments (GMP Class C, ISO 7, ISO 8). In-house collaboration with our subsidiary Fischer Söhne Extrusion AG also enables integrated solutions that include extrusion blow moulding outside of cleanroom environments.

With 18 injection moulding machines – several with clamping forces up to 500 tons in cleanroom conditions – we manufacture everything from simple packaging to complex medical components. Using materials like PS, PP, technical thermoplastics, and PE-UHMW, we ensure durable, high-quality solutions for demanding applications.

Our production processes are certified according to ISO 9001, ISO 13485, and BRC Global Standard, ensuring maximum safety and hygiene. To guarantee precision, we rely on tactile and optical 3D measuring machines, while specialized analyses such as CT scans are performed in cooperation with expert partners. Continuous monitoring and systematic Failure Mode and Effects Analysis (FMEA) underpin our sustainable quality management.

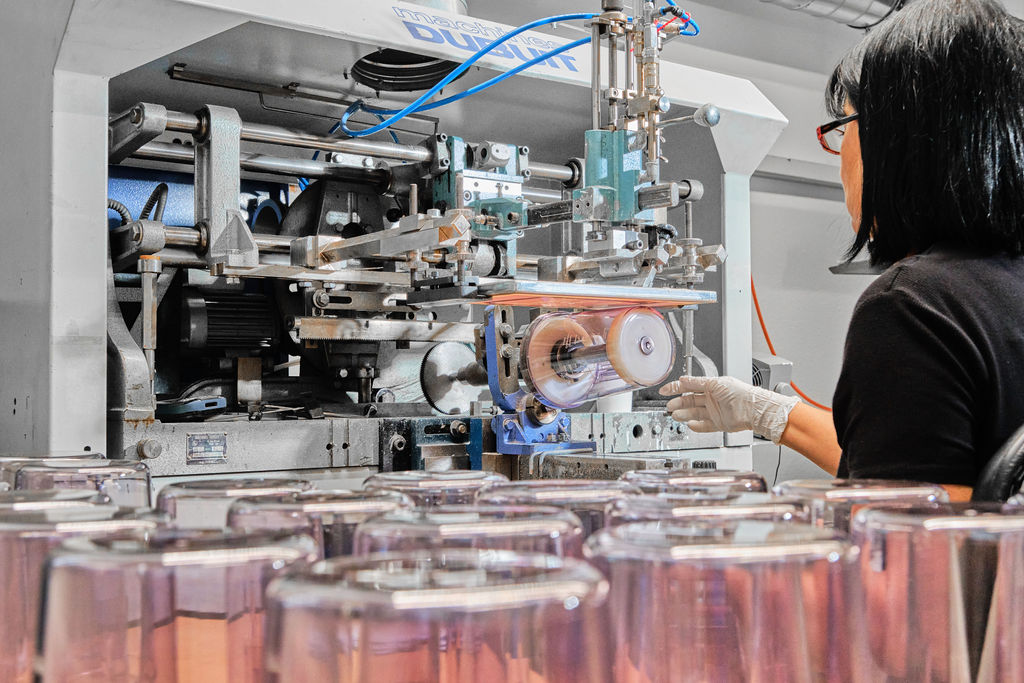

Assembly: Efficient Integration and Automated Packaging

Efficient assembly and automated packaging under controlled conditions

Efficient assembly and automated packaging under controlled conditions

In our Assembly department, we combine individual parts into subassemblies or finished products – from simple containers to complex multi-component solutions. Depending on project requirements, we apply manual assembly, inline assembly, or fully automated packaging systems in the cleanroom, ensuring maximum efficiency and hygiene in the final packaging process.

Optimized warehouse logistics for efficient material flow and flexible deliveries

Optimized warehouse logistics for efficient material flow and flexible deliveries

Thanks to our flexible infrastructure and many years of experience, we produce assemblies efficiently and reliably, tailored precisely to customer needs. Our centralized logistics, optimized warehouse capacities, and silo storage for bulk materials ensure a smooth material flow and flexible delivery options adapted to your supply chain.